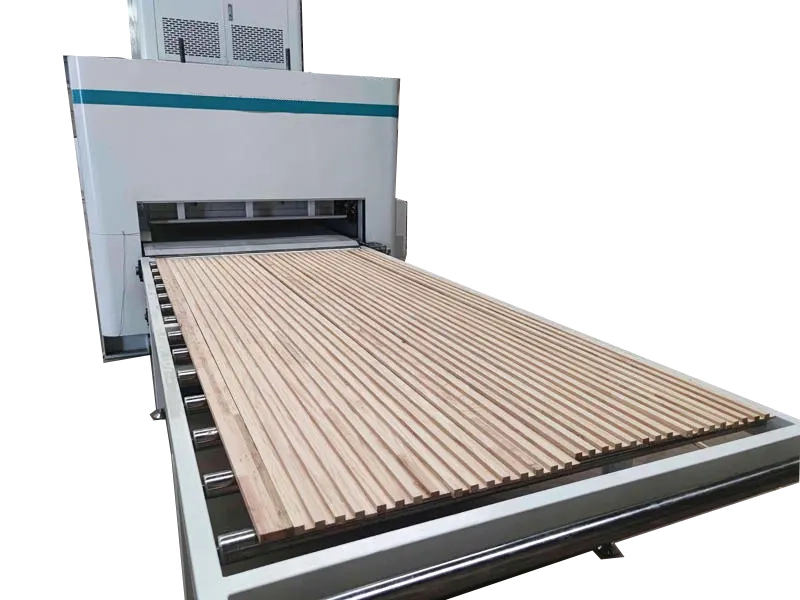

High frequency wood board edge glue joining press machine is newly designed woodworking furniture board edge glue joining, right angle board joining, laminated wood joining, cabinet board joining, door edge banding, “L” type door pocket line joining. It is of PLC control, high frequency heating, advanced automatic control and high efficiency.

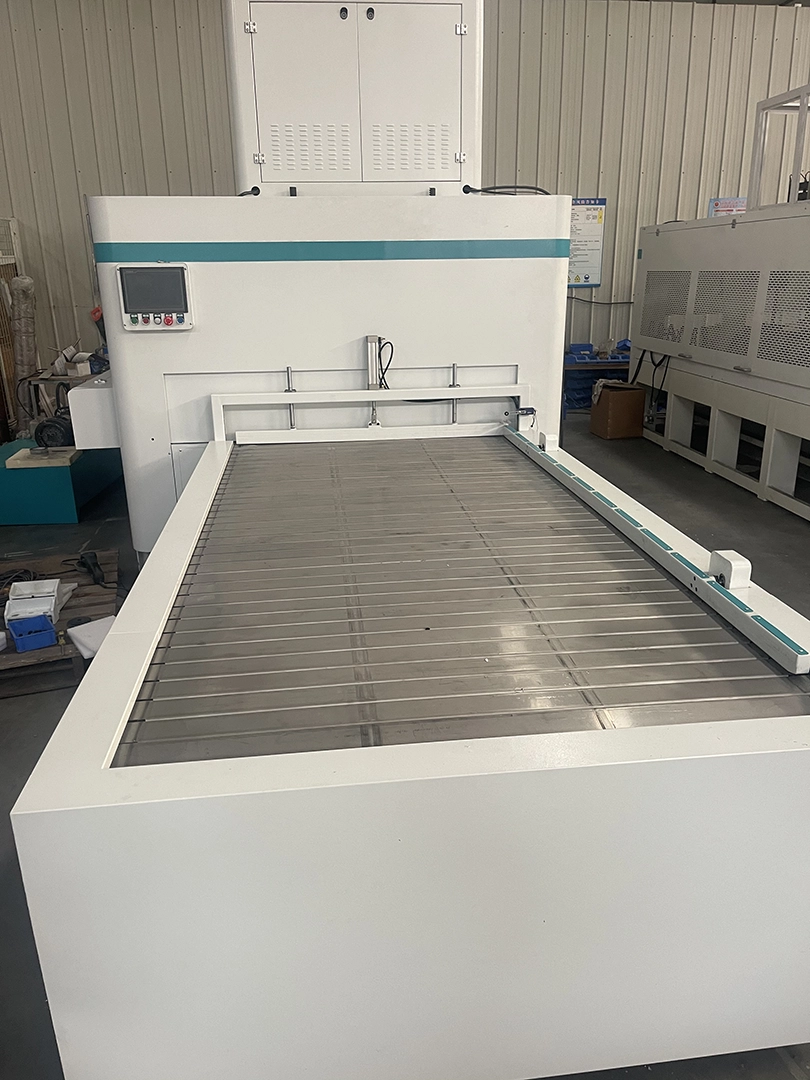

Adopts conveyor belt type charging and discharging, pp or stainless steel belts are light and easy to clean. Heavy machine frame design, stable performance, better plainness, sanding amount only 0.5mm, high timber output rate.

Advantages

Workers can place wood pieces in right position, avoiding dislocation problem and damage cylinder.

Locate high frequency generator and hydraulic system on the top of machine, saving factory space.

Low power costs: HF power only heat glue line, save the power.

Machine working table processed by non-cohesive material. Glue is easy to remove and assure panel quality.

High efficiency: HF heating 1-2minutes finish one standard panel(8×4 feet, 20mm thick ). In winter, the efficiency is obviously higher than the traditional clamp carrier.

Labor saving: Automatic control. One button can finish whole cycle. Compared with the traditional wooden board joining machine, the average output rate is 5%-15% higher.

Top working table designed with lifting device. Make sure panel straight and flatness.Save more wood material for next sanding process.

Working table size can be custom made as customer requirements.

No pollution: HF power only needs electricity, dust free and clean.

Specs – High frequency wood board edge glue joining press machine

| Model | BP-2513-ABT | BP-3213-ABT | BP-4213-ABT | BP-5213-ABT | BP-6213-ABT |

|---|---|---|---|---|---|

| Control | PLC, HMI Screen | PLC, HMI Screen | PLC, HMI Screen | PLC, HMI Screen | PLC, HMI Screen |

| Working Table | 2500*1300mm | 3000*1300mm | 4200*1300mm | 5200*1300mm | 6200*1300mm |

| Thickness | 5-90mm | 5-90mm | 5-90mm | 5-90mm | 5-90 |

| Vertical Pressure | 20 Tons | 20 Tons | 30 Tons | 40 Tons | 50 Tons |

| Side Pressure | 38 Tons | 50 Tons | 68 Tons | 76 Tons | 90 Tons |

| HF Frequency | 6.78MHz | 6.78MHz | 6.78MHz | 6.78MHz | 6.78MHz |

| HF Power | 20 Kw | 30 Kw | 40 Kw | 50 Kw | 50kw |

| Feeding | Automatic conveyor belts | Automatic conveyor belts | Automatic conveyor belts | Automatic conveyor belts | Automatic conveyor belts |

| Automatic Stacking | Optical | Optical | Optical | Optical | Optical |